Turning

Turning is a manufacturing process where a cutting tool is used to remove material from a rotating workpiece. This process is carried out on a machine called a lathe, which holds and spins the workpiece on its axis while the cutting tool is advanced into it. Turning is primarily used to produce cylindrical parts, such as shafts, rods, and spindles, by cutting away unwanted material from the workpiece.

The turning process allows for various features to be machined, including straight and tapered surfaces, grooves, threads, and other complex geometries. The cutting tool moves linearly while the workpiece rotates, ensuring precise and even removal of material. The depth of the cut, the speed of the workpiece’s rotation, and the rate of the tool’s advance can be adjusted to achieve the desired dimensions and finish.

Turning can be performed manually on a traditional lathe or with the aid of computer numerical control (CNC) technology, where the cutting process is automated and controlled by computer programming. This versatility makes turning a fundamental and widely used technique in the manufacturing industry, suited for both high-volume production and one-off jobs. The process is commonly used with a variety of materials, including metals, plastics, and wood.

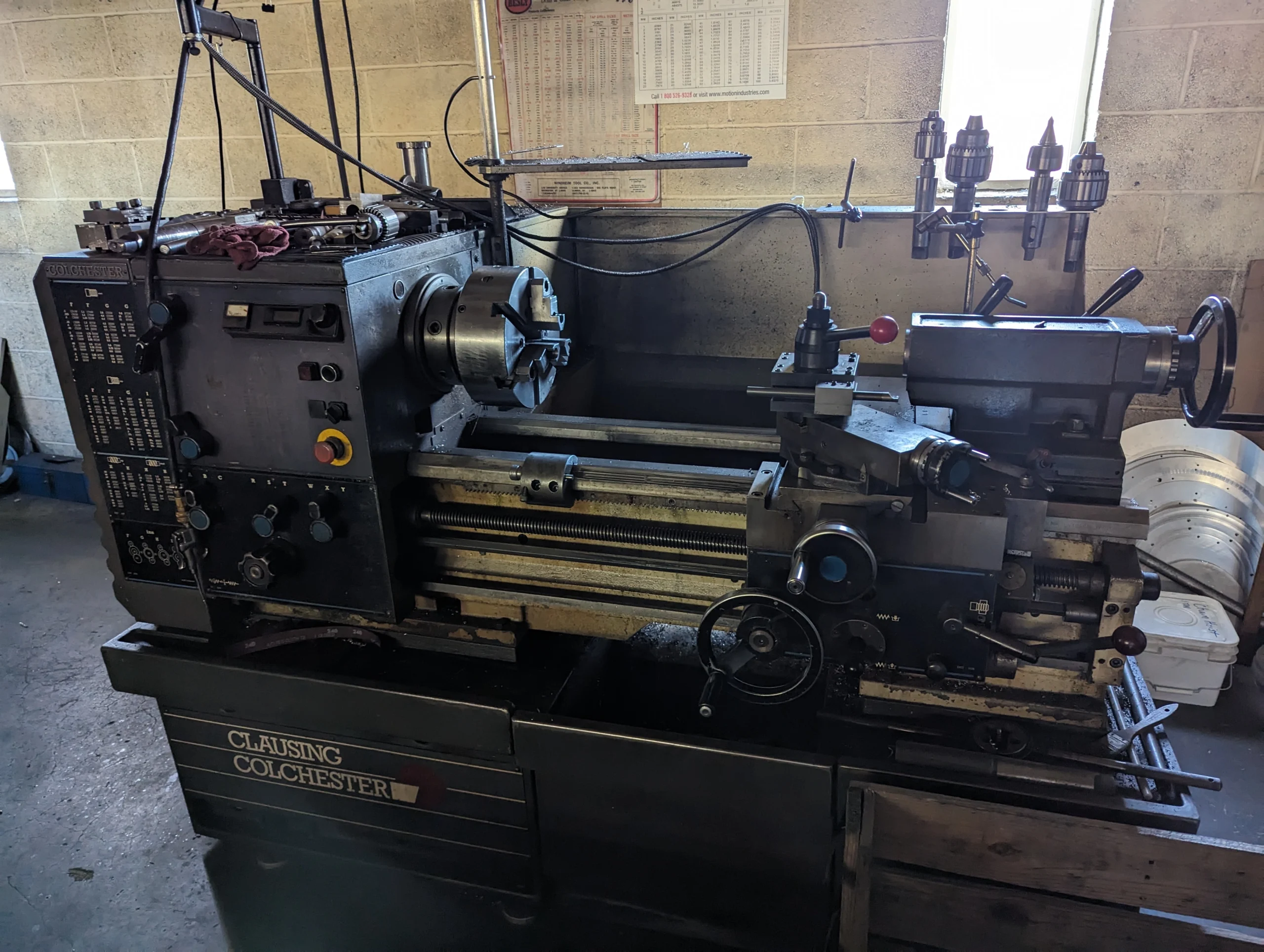

We have brand new lathes to maintain the highest precision as well as traditional lathes for flexability.

equipment